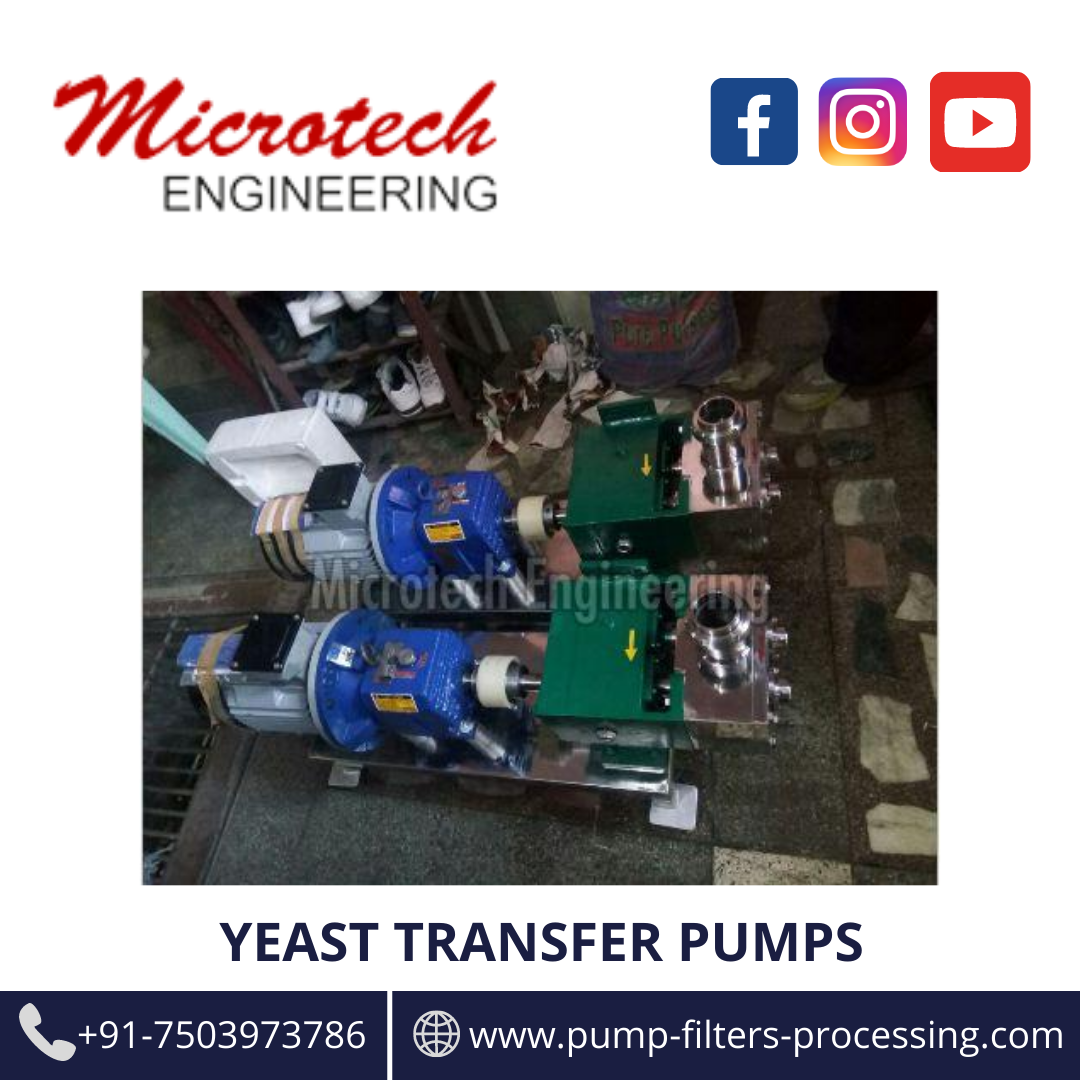

We are one-step ahead of our competitors in manufacturing and wholesaling a wide range of Jaketed Stainless Steel YEAST TRANSFER PUMP. These find their wide application in various industries including food processing, beverages, dairy, pharmaceutical and many other allied industries. ergonomic design of these pumps reflect the hard labor and long research work of our experienced engineers. Besides, these pumps also ensure easy installation, corrosion resistance and long functional efficiency. Specifications

As the rotors start to rotate, an expanding cavity is formed by rotation of the lobes which creates a vacuum at the inlet port, drawing liquid in pumping chamber. The product liquid is carried between the lobes and positively displaced, thereby sealing itself against the internal faces of the pump casing. The other lobe chamber is filed with the product liquid and about to commence it's discharge cycle.

Finally the product liquid is forced or pressed out of discharge port of the pump in continuous smooth flow and pressure generated by the meshing of the lobe rotors Microtech Enginering Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, Pharmaceutical, and biotechnology. They are popular in these Diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics.These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe.Rotary lobe pumps are Non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous. How Lobe Pumps Work Liquid flows into the cavity and is trapped by the lobes as they rotate : Lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timinggears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection.

We can also provide you the filter housing with.

We are specialized in simplex / duplex type housings.

We are also giving the housings with rubber lining.

-

Advantages

- Pass medium solids

- No metal-to-metal contact

- Superior CIP/SIP capabilities

- Long term dry run (with lubrication to seals)

- Non-pulsating discharge

-

Disadvantages

- Requires timing gears

- Requires two seals

- Reduced lift with thin

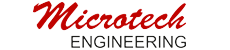

| Type | Transfer Pump |

| Certification | CE Certified |

| Weight | 100-300kg, 300-500kg |

| Color | Multi Colour |

| Rated Voltage | 230V |

| Rated Power | 1-5kw, 10-15kw, 15-20kw |

| Driven Type | Electricity |

| Features | Cost Effective, Durable |

| Warranty | 1 Year |

| Automation Grade | Automatic |